"TurboSloth" (TheTurboSloth)

"TurboSloth" (TheTurboSloth)

01/20/2014 at 14:19 • Filed to: None

0

0

10

10

"TurboSloth" (TheTurboSloth)

"TurboSloth" (TheTurboSloth)

01/20/2014 at 14:19 • Filed to: None |  0 0

|  10 10 |

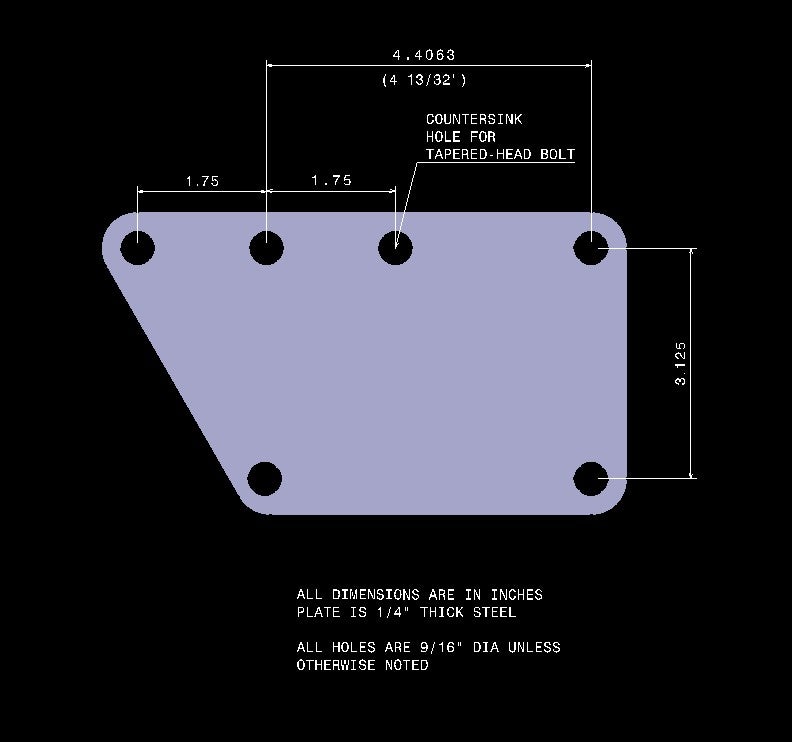

Basically, what type of metal would you use? I know how do use SolidWorks and make basic stuff. Given that I also know the measurements, and I draft up the stuff on solidworks, would it be advisable to get it made myself? How hard could it be? It would just be a sheet of very thick metal with holes in it right?

I only ask this because I know my college has a metalshop that is closed off to students, however, I know someone who works there who can make these mounts.

This is all hypothetical.

LuczOr

> TurboSloth

LuczOr

> TurboSloth

01/20/2014 at 14:29 |

|

If they are just flat plate mounts, it should be very easy. The mounts in the picture look like early GM V8 (350) to LSx conversion mounts. There are a several variants you can buy online, but most people just make their own. Just make them from some steel. The temper and type of steel is almost inconsequential since tensile strength is all that really matters. Even U shaped mounts can be made very easy by welding steel plates together. I guess it depends on how complicated the mount is.

Paul, Man of Mustangs

> TurboSloth

Paul, Man of Mustangs

> TurboSloth

01/20/2014 at 14:32 |

|

Any mild steel should be fine. Something between 7 gauge and 3/16" plate. You could also use 3/4"-1" .120-wall tubing will work where you need it.

Bullitt Ride

> TurboSloth

Bullitt Ride

> TurboSloth

01/20/2014 at 14:33 |

|

If all you are trying to make is what's shown in that picture then that's pretty easy. If you draw it up in solid works (or any 2D CAD package for that matter) simply print it 1:1 scale and cut out the outline to use as a template. Just your run of the mill flat bar steel will be fine. You can cut the angle on a chop saw and round the edges on a belt sander. With the template taped to the flat bar so that it doesn't move use a center punch and a hammer to mark the center of the holes. Then use a drill press to drill and countersink as necessary.

505Turbeaux

> TurboSloth

505Turbeaux

> TurboSloth

01/20/2014 at 14:35 |

|

Joe_Limon

> TurboSloth

Joe_Limon

> TurboSloth

01/20/2014 at 14:41 |

|

For plates, it is super easy, in solidworks right click on a surface and export as dxf, any shop with a cnc plasma/laser/water jet should be able to use the dxf to get you accurate parts relatively cheaply. For custom welding/etc, either do it yourself, or bring it into a reputable welding shop. I recommend bringing the whole car in unless you know they can for sure meet your drawing tolerances.

TurboSloth

> 505Turbeaux

TurboSloth

> 505Turbeaux

01/20/2014 at 14:43 |

|

If only I could afford a milling machine (thats a milling machine right?)

505Turbeaux

> TurboSloth

505Turbeaux

> TurboSloth

01/20/2014 at 14:46 |

|

yup, I know my grandpa had one growing up. No way to move it and no place to put it so it was sold

mycarneverruns87

> TurboSloth

mycarneverruns87

> TurboSloth

01/20/2014 at 15:19 |

|

Those are 1/4" thick steel. They wouldn't be too hard to make. Here are the dimensions of the shown mount.

JoelA237

> TurboSloth

JoelA237

> TurboSloth

01/22/2014 at 03:01 |

|

Regular mild steel, hot roll, avoid galvanized or aluminized unless you want to do alot of grinding to get a clean weld. You could make what is in that picture pretty easy. If you are patient, have good measurements, and time, you could knock those plates out with an angle grinder with a cutoff wheel and a hand drill.

Philbert/Phartnagle

> TurboSloth

Philbert/Phartnagle

> TurboSloth

01/22/2014 at 19:56 |

|

I usually use 3/16" or 1/4" thick mild steel plate for those types of mounts. (Not really considered very "thick" metal at all.)

Not having much in the way of "fancy" machining tools I make do with a sawzall and a metal cutting blade to rough cut the part, then smooth the edges with a belt sander and drill the holes with a hand drill.

It is not hard to do at all, BUT in a lot of cases simple pieces like shown in your picture can be bought for less, if you figure anything at all for your time and wear and tear on your tools and expendables.